Research and development in industrial refrigeration equipment

Since the establishment of the Company in 1989, Tucal’s main priorities have always been focused on product innovation and continuous improvement to deliver optimum reliability, durability, efficiency and functionality of our equipment.

Research and development in Tucal is not part of an external process, but the philosophy that the founder, Fernando Mariño, imprinted on the company and the second generation of the family, currently leading Tucal.

Technology forged in offshore fishing vessels

The origins of Tucal are closely linked to fishing vessels, where the available space is always scarce, the electrical power is difficult to increase and timings for the installation on board are always extremely short. The most demanding shipowners set challenges that were overcome with constant developments, and this experience was later transferred to other types of installations.

This is precisely how we developed our first horizontal plate freezer as an alternative to blast freezers, thus reducing the space required to freeze blocks, the initial investment and also the electrical consumption, while improving the quality of freezing.

That first model of horizontal plate freezer was later adapted to work with thermostatic expansion valves without loss of performance, reducing the space in the machine room, simplifying the refrigeration system and also minimising the required initial investment. That was the basis for the first compact horizontal plate freezer.

The first model of vertical plate freezer, mainly focused on bulk freezing, was intended to improve other solutions in the market in terms of sustainability (low refrigerant load), safety (reduction of the working pressure), reliability and simplicity (elimination of the electrical components and improvement of the hydraulic system).

Vertical plate freezer loading.

Simple and reliable industrial refrigeration systems

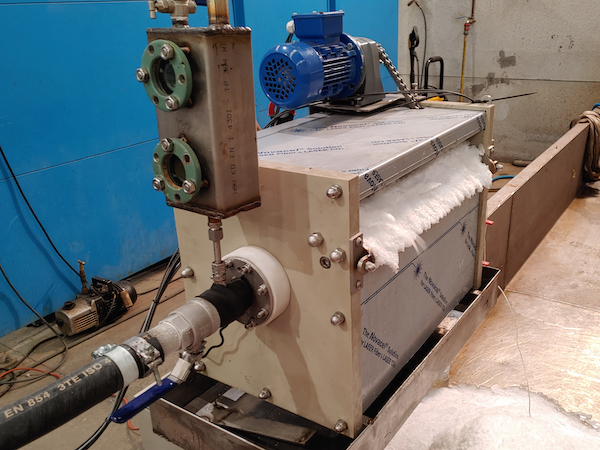

To meet the demands of fishing industries, Tucal designed the first flake ice machines with horizontal drum, capable of withstanding the most severe environmental conditions as a result of an exhaustive material selection and also of the thorough design of every component of the ice machine.

Throughout the 2000s, the marine air conditioning activity had a considerable impact to the business, mainly in medium-size and large ferries. The demand in this business sector led to the development of modular production of refrigerating installations, aiming to save time without losing the quality and safety in operation that characterize Tucal. These improvements helped optimise the design and transport to final destination.

High-quality freezing solutions designed to optimise production

Patented solutions for plate freezers

While improving contact plate freezers, Tucal has registered —among others— patents of diverse components of plates, the freezer with automatic unloading system or a model of IQF plate freezer.

Aiming to improve the performance, reliability and utility of the equipment, Tucal decided to manufacture it using the best materials available in the market: stainless steel, high quality extruded aluminium profiles and high density polyethylene HD PE500, suitable for the food industry.

Sustainable ice machines and plate freezers

Environmental awareness and energy efficiency are also challenges that Tucal has faced by innovating and developing optimised solutions to reduce the refrigerant needs, thus increasing durability of the equipment and contributing to sustainability.

Always aiming to satisfy the requirements of our worldwide customers, this constant innovative inertia led Tucal engineers to design equipment ready to work with secondary refrigerants.